The research area of lightweight design and simulation deals with a wide range of issues relating to the digital development of lightweight structures. With the help of numerical simulations, similarity mechanics and machine learning (ML), precise and application-oriented approaches to material modelling, structural simulation and process simulation are developed. In addition to individual modelling approaches, the focus is on connecting the sub-areas. Thus, the development process can be holistically captured and optimised through multi-scale and multi-model simulation approaches. Furthermore, the sensor-based linking of the digital twin with the real product offers the possibility of data-based and automated further development of lightweight structures.

Topics

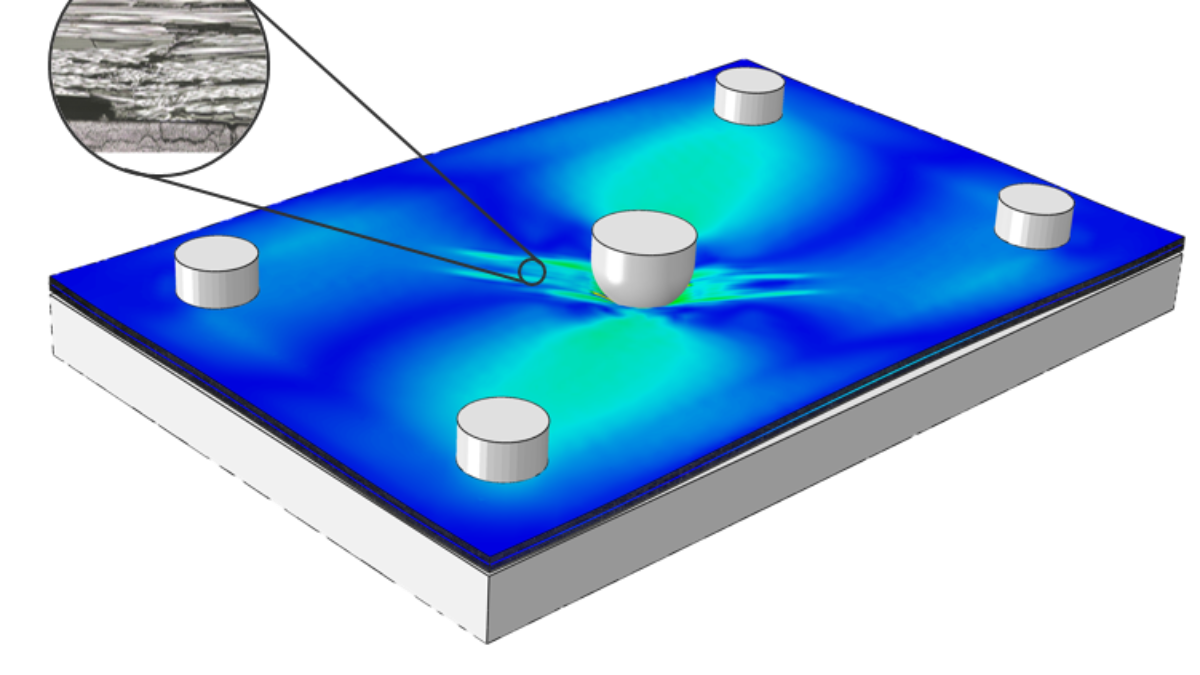

- Structual simulation

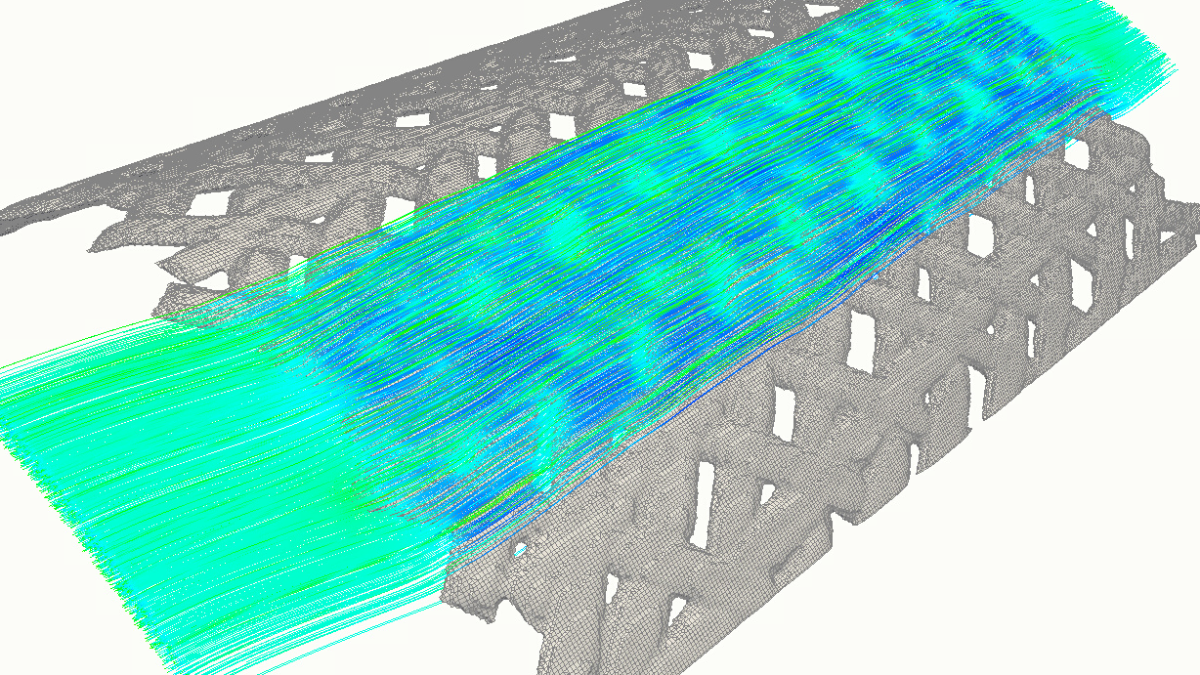

Design of lightweight structures from material to the optimized component - Process simulation

Development of process simulations to predict manufacturing parameters and process boundary conditions - Virtual material characterization

Development of methods for efficient material characterization by linking simulation and experimentation - Interconnected design methods

Development of interconnected design methods by coupling analysis and simulation models with real processes and structures

Code / Programme

On the Code / Programs page you can find various scripts and programs for microscopic and mesoscopic model generation, execution and evaluation of simulations, structural evaluation and tools for manufacturing optimisation, which are developed as part of active research projects and are continuously modified and improved.

Theses

Currently advertised theses of the research group can be found in the ILIAS-Gruppe "Studentische Abschlussarbeiten". The listing can only be viewed by students of the University of Stuttgart, therefore please join the ILIAS group. There is no guarantee that the list is complete. If the topic of your choice is not available, you can also send a speculative application for a thesis to the respective staff member.

Publications

Journals and Books

2024

- Carosella, Stefan, Sebastian Hügle, Florian Helber und Peter Middendorf. 2024. A short review on recent advances in automated fiber placement and filament winding technologies. Composites Part B: Engineering 287 (Dezember): 111843. doi:10.1016/j.compositesb.2024.111843, http://dx.doi.org/10.1016/j.compositesb.2024.111843.

- Kannenberg, Fabian, Christoph Zechmeister, Marta Gil Pérez, Yanan Guo, Xiliu Yang, David Forster, Sebastian Hügle, u. a. 2024. Toward reciprocal feedback between computational design, engineering, and fabrication to co-design coreless filament-wound structures. Journal of Computational Design and Engineering 11: 374–394. doi:10.1093/jcde/qwae048, .

2023

- Facciotto, Silvio, Pavel Simacek, Suresh G. Advani, Anthony Pickett und Peter Middendorf. 2023. Modeling formation and evolution of voids in unsaturated dual scale preforms in Resin Transfer Molding processes. Composites Part A: Applied Science and Manufacturing 173 (Oktober): 107675. doi:10.1016/j.compositesa.2023.107675, .

- Gil Pérez, Marta, Pascal Mindermann, Christoph Zechmeister, David Forster, Yanan Guo, Sebastian Hügle, Fabian Kannenberg, u. a. 2023. Data processing, analysis, and evaluation methods for co-design of coreless filament-wound building systems. Journal of Computational Design and Engineering 10 (Juni): 1460–1478. doi:10.1093/jcde/qwad064, https://doi.org/10.1093/jcde/qwad064.

- Böhringer, Pauline, Daniel Sommer, Thomas Haase, Martin Barteczko, Joachim Sprave, Markus Stoll, Celalettin Karadogan, David Koch, Peter Middendorf und Mathias Liewald. 2023. A strategy to train machine learning material models for finite element simulations on data acquirable from physical experiments. Computer Methods in Applied Mechanics and Engineering 406 (März): 115894. doi:10.1016/j.cma.2023.115894, .

2022

- Czichos, R., T. Bergmann, F. Moldering und P. Middendorf. 2022. Comparison of numerical modelling approaches for the residual burst pressure of thick type IV composite overwrapped pressure vessels related to low-velocity impact. International Journal of Pressure Vessels and Piping 199 (Oktober): 104770. doi:10.1016/j.ijpvp.2022.104770, https://doi.org/10.1016%2Fj.ijpvp.2022.104770.

- Hügle, Sebastian, Enis Genc, Jörg Dittmann und Peter Middendorf. 2022. Offline Robot-Path-Planning and Process Simulation for the Structural Analysis of Coreless Wound Fibre-Polymer Composite Structures. Key Engineering Materials 926 (August): 1445–1453. doi:10.4028/p-970esd, .

- Hügle, Sebastian, Enis Genc, Jörg Dittmann und Peter Middendorf. 2022. Offline Robot-Path-Planning and Process Simulation for the Structural Analysis of Coreless Wound Fibre-Polymer Composite Structures. Key Engineering Materials 926 (August): 1445–1453. doi:10.4028/p-970esd, .

- Sommer, Daniel, André Haufe und Peter Middendorf. 2022. A Machine Learning Material Model for Structural Adhesives in Finite Element Analysis. International Journal of Adhesion and Adhesives (April): 103160. doi:10.1016/j.ijadhadh.2022.103160, .

- Schwingel, Johannes und Peter Middendorf. 2022. Topological design using multivariate laminate stackings for tailored fiber placement. Journal of Composite Materials (April). doi:10.1177/00219983221085721, .

- Pérez, M Gil, C Zechmeister, F Kannenberg, P Mindermann, L Balangé, Y Guo, S Hügle, u. a. 2022. Computational co-design framework for coreless wound fibre–polymer composite structures. Journal of Computational Design and Engineering 9 (Februar): 310–329. doi:10.1093/jcde/qwab081, https://doi.org/10.1093%2Fjcde%2Fqwab081.

- Pérez, M Gil, C Zechmeister, F Kannenberg, P Mindermann, L Balangé, Y Guo, S Hügle, u. a. 2022. Computational co-design framework for coreless wound fibre–polymer composite structures. Journal of Computational Design and Engineering 9 (Februar): 310–329. doi:10.1093/jcde/qwab081, https://doi.org/10.1093%2Fjcde%2Fqwab081.

2021

- Schlotthauer, Tristan und Peter Middendorf. 2021. Hollow stereolithographic structures reinforced by short carbon fibres. In: JEC Composite Magazine, 143:21–24. November.

- Ackermann, Annika C., Stefan Carosella, Markus Rettenmayr, Bronwyn L. Fox und Peter Middendorf. 2021. Rheology, dispersion, and cure kinetics of epoxy filled with amine-- and non--functionalized reduced graphene oxide for composite manufacturing. Journal of Applied Polymer Science 139 (September): 51664. doi:10.1002/app.51664, .

- Facciotto, Silvio, Pavel Simacek, Suresh G. Advani und Peter Middendorf. 2021. Modeling of anisotropic dual scale flow in RTM using the finite elements method. Composites Part B: Engineering 214: 108735. doi:10.1016/j.compositesb.2021.108735, .

- Urban, Fabian, Bo Armbruster und Peter Middendorf. 2021. Development and validation of a method for linear-viscoelastic characterization of the dynamic complex modulus of short-fiber reinforced plastics using flexural resonances. Polymer Testing 94: 107055. doi:10.1016/j.polymertesting.2021.107055, .

- Yong, A.X.H., A. Aktas, D. May, A. Endruweit, S. V. Lomov, S. Advani, P. Hubert, u. a. 2021. Experimental characterisation of textile compaction response: A benchmark exercise. Composites Part A: Applied Science and Manufacturing 142: 106243. doi:10.1016/j.compositesa.2020.106243, .

2020

- Engelfried, Mathias, Benedikt Aichele und Peter Middendorf. 2020. Investigation of the Friction between Dry and Wetted Carbon Filaments. Procedia Manufacturing 47: 60–64. doi:10.1016/j.promfg.2020.04.130, .

- Damm, Andreas M., Claudio Spitzmüller, Andreas T. S. Raichle, Andre Bühler, Philipp Weißgraeber und Peter Middendorf. 2020. Deep learning for impact detection in composite plates with sparsely integrated sensors. Smart Materials and Structures 29: 125014. doi:10.1088/1361-665X/abb644, .

- Sachse, R., A. K. Pickett und P. Middendorf. 2020. Simulation of impact and residual strength of thick laminate composites. Composites Part B: Engineering 195: 108070. doi:10.1016/j.compositesb.2020.108070, .

- Rihaczek, Gabriel, Maximilian Klammer, Okan Basnak, Jan Petrs, Benjamin Grisin, Hanaa Dahy, Stefan Carosella und Peter Middendorf. 2020. Curved Foldable Tailored Fiber Reinforcements for Moldless Customized Bio-Composite Structures. Proof of Concept: Biomimetic NFRP Stools. Polymers 12. doi:10.3390/polym12092000, .

- Zink, Dennis, Maximilian Huber und Peter Middendorf. 2020. FormPATCH - Forming of Complex Composite Structures using Patching Technologies. Procedia Manufacturing 47: 100–106. doi:10.1016/j.promfg.2020.04.143, .

- Czichos, Ruben, Oscar Bareiro, Anthony K. Pickett, Peter Middendorf und Thomas Gries. 2020. Experimental and numerical studies of process variabilities in biaxial carbon fiber braids. International Journal of Material Forming. doi:10.1007/s12289-020-01541-4, .

- Muhs, Fabian, Simon Thissen und Peter Middendorf. 2020. Virtual process chain for optimization of sandwich foldcores under flatwise compression. Thin-Walled Structures 157: 107121. doi:10.1016/j.tws.2020.107121, .

- Nebe, M., A. Soriano, C. Braun, P. Middendorf und F. Walther. 2020. Analysis on the mechanical response of composite pressure vessels during internal pressure loading: FE modeling and experimental correlation. Composites Part B: Engineering: 108550. doi:10.1016/j.compositesb.2020.108550, .

2019

- Raichle, A., Florian Ritter, M. Vinot, J. Dittmann, F. Fritz, L. Ott, C. Liebold, u. a. 2019. Weiterentwicklung des Digitalen Prototyps zum Digitalen Fingerabdruck. ATZ-Magazin 03/2019 (März).

- Harder, Nadine, Yves Klett, Sumee Park, Philip Leistner und Peter Middendorf. 2019. Bauphysikalische Untersuchung von Sandwichelementen. Bauphysik 41: 314–323. doi:10.1002/bapi.201900025, .

- Pickett, Anthony K. 2019. Process and mechanical modelling of engineering composites. Stuttgart: IFB (Institute of Aircraft design).

- May, D., A. Aktas, S. G. Advani, D. C. Berg, A. Endruweit, E. Fauster, S. V. Lomov, u. a. 2019. In-Plane Permeability Characterization of Engineering Textiles Based On Radial Flow Experiments: A Benchmark Exercise. Composites Part A: Applied Science and Manufacturing. doi:10.1016/j.compositesa.2019.03.006, .

- Klett, Yves, Fabian Muhs und Peter Middendorf. 2019. Analysis of Static and Dynamic Behavior of Thick-Walled PALEO Elements. In: Volume 5B: 43rd Mechanisms. doi:10.1115/DETC2019-97155, .

- Pickett, Anthony K. 2019. Introduction to Process and Mechanical Modelling of Engineering Composites. Stuttgart: IFB (Institute of Aircraft design).

- Dittmann, Jörg und Peter Middendorf. 2019. Der digitale Prototyp: Ganzheitlicher digitaler Prototyp im Leichtbau für die Großserienproduktion. 1st ed. 2019. ARENA2036. https://doi.org/10.1007/978-3-662-58957-1.

- Fernández, Daniel, Benjamin Begemann, Peter Middendorf und Peter Horst. 2019. Investigation of the buckling and load-bearing behaviour of selectively stitched stiffened CFRP panels under multiaxial loading. CEAS Aeronautical Journal 10: 703–717. doi:10.1007/s13272-018-0343-y, .

- McGarrigle, Cormac, Daniel Fernández, Peter Middendorf, Thomas Dooher, John Kelly, Alistair McIlhagger, Eileen Harkin-Jones und Edward Archer. 2019. Extruded high-temperature thermoplastic tufting yarns for enhanced mechanical properties of composites. Journal of Reinforced Plastics and Composites 24: 073168441988636. doi:10.1177/0731684419886368, .

- Diermann, Verena und Peter Middendorf. 2019. Automatic Evaluation of Structural Integrity in Crashworthiness Simulations Using Image Analysis. International Journal of Automotive Technology 20: 65–72. doi:10.1007/s12239-019-0006-y, .

2018

- Muhs, Fabian, Yves Klett und Peter Middendorf. 2018. Automated numerical process chain for the design of folded sandwich cores. In: Origiami 7. August.

- Grzeschik, Marc, Yves Klett und Peter Middendorf. 2018. Reality Check - Mechanical Potential of Tessellation-based Foldcore Materials. In: Origiami 7. August.

- Pickett, Anthony. 2018. Process and Mechanical Modelling of Engineering Composites. University Stuttgart: IFB. https://www.amazon.co.uk/Process-Mechanical-Modelling-Engineering-Composites/dp/3981953908?SubscriptionId=AKIAJ5I32ZDGB7F3VSDA&tag=ws&linkCode=xm2&camp=2025&creative=165953&creativeASIN=3981953908.

- Wagner, Tim, Sebastian Heimbs, Florian Franke, Uli Burger und Peter Middendorf. 2018. Experimental and numerical assessment of aerospace grade composites based on high-velocity impact experiments. Composite Structures 204: 142–152. doi:10.1016/j.compstruct.2018.07.019, .

- Wellekötter, J., S. Baz, Johannes Schwingel, C. Bonten, Götz Theo Gresser und P. Middendorf. 2018. Kohlenstofffasern im Kreislauf halten. Kunststoffe 9.

- Kraemer, Matthias, Thomas Dauser, Peter Middendorf und Thomas Bauernhansl. 2018. Correlation between subjective perception and objective parameters for the characterisation of fibre print-through on surfaces of class A carbon fibre reinforced plastics via multidimensional scaling. Composites Part A: Applied Science and Manufacturing 115: 166–174. doi:10.1016/j.compositesa.2018.09.025, .

- Czichos, R., O. Bareiro, A. K. Pickett, P. Middendorf und T. Gries. 2018. Influence of process induced defects for biaxial carbon fiber braids. IOP Conference Series: Materials Science and Engineering 406: 12047. doi:10.1088/1757-899X/406/1/012047, .

- Middendorf, Peter, Patrick Böhler, Florian Gnädinger, Frieder Heieck und Karin Birkefeld. 2018. 8.3 Design Study for a Carbon Composite Manipulator. In: Comprehensive Composite Materials II, 47–60. Elsevier. doi:10.1016/B978-0-12-803581-8.10048-7, .

- Birkefeld, Karin, Anthony Pickett und Peter Middendorf. 2018. 8.5 Virtual Design and Optimisation of Braided Structures Considering Production Aspects of the Preform. In: Comprehensive Composite Materials II, 85–97. Elsevier. doi:10.1016/B978-0-12-803581-8.10054-2, .

- Kraemer, M., P. Middendorf und T. Bauernhansl. 2018. Investigation on the influence of humidity on the topography of surfaces of polymeric class A carbon fiber reinforced plastics. Journal of Composite Materials 52: 4247–4260. doi:10.1177/0021998318778891, .

2017

- Heidenreich, Bernhard, Dietmar Koch, Harald Kraft und Yves Klett. 2017. C/C--SiC sandwich structures manufactured via liquid silicon infiltration. Journal of Materials Research 32 (September): 3383–3393. doi:10.1557/jmr.2017.208, .

- Sachse, Ronny, A. K. Pickett, W. Essig und Peter Middendorf. 2017. Experimental and numerical investigation of the influence of rivetless nut plate joints on fatigue crack growth in adhesively bonded composite joints. International Journal of Fatigue 105: 262–275. doi:10.1016/j.ijfatigue.2017.08.001, .

2016

- Böhler, Patrick, A. K. Pickett und Peter Middendorf. 2016. Finite element method (FEM) modeling of overbraiding. In: Advances in Braiding Technology, 457–475. Elsevier. doi:10.1016/B978-0-08-100407-4.00019-3, .

- Mallach, A., Frank Härtel, Frieder Heieck, Jan-Philipp Fuhr, Peter Middendorf und M. Gude. 2016. Experimental comparison of a macroscopic draping simulation for dry non-crimp fabric preforming on a complex geometry by means of optical measurement. Journal of Composite Materials. doi:10.1177/0021998316670477, .

- Finkenwerder, F. A., M. Geistbeck und Peter Middendorf. 2016. Study on the validation of ring filament winding methods for unidirectional preform ply manufacturing. Advanced Manufacturing: Polymer & Composites Science 2: 103–116. doi:10.1080/20550340.2016.1262090, .

- Böhler, Patrick, Jörg Dittmann, Daniel Michaelis und Peter Middendorf. 2016. Process Simulation as Part of Industry 4.0. Lightweight Design 9. doi:10.1007/s35725-016-0070-4, .

- Bulat, Martina, Holger Ahlborn, Florian Gnädinger und D. Michaelis. 2016. Braided carbon fiber composites. In: Advances in Braiding Technology, 383–394. Elsevier. doi:10.1016/B978-0-08-100407-4.00015-6, .

- Nezami, Farbod, Jan-Philipp Fuhr, Diego Schierle, Chokri Cherif und Peter Middendorf. 2016. Hochqualitative CFK-Umformteile durch synchrone Bauteil- und Prozessentwicklung. Lightweight Design 9: 52–58. doi:10.1007/s35725-016-0012-1, .

- Böhler, Patrick, Jörg Dittmann, Daniel Michaelis und Peter Middendorf. 2016. Prozesssimulation als Basis für die Industrie 4.0. Lightweight Design 9: 14–19. doi:10.1007/s35725-016-0062-4, .

- Jäger, Sebastian, Anthony Pickett und Peter Middendorf. 2016. A Discrete Model for Simulation of Composites Plate Impact Including Coupled Intra- and Inter-ply Failure. Applied Composite Materials 23: 179–195. doi:10.1007/s10443-015-9455-2, .

- Fischer, Sebastian. 2016. A Material Model for FE-Simulation of UD Composites. Applied Composite Materials 23: 197–217. doi:10.1007/s10443-015-9456-1, .

2015

- Stens, Christine und Peter Middendorf. 2015. Computationally efficient modeling of the fatigue behaviour of composite materials. International Journal of Fatigue 80. doi:10.1016/j.ijfatigue.2015.05.001, .

- Böhler, Patrick, Stefan Carosella, Christopher Goetz und Peter Middendorf. 2015. Path Definition for Tailored Fiber Placement Structures Using Numerical Reverse Draping Approach. Key Engineering Materials 651-653: 446–451. doi:10.4028/www.scientific.net/KEM.651-653.446, .

- Sirtautas, Justas, Anthony Pickett und A. George. 2015. Materials Characterisation and Analysis for Flow Simulation of Liquid Resin Infusion. Applied Composite Materials 22: 323–341. doi:10.1007/s10443-014-9411-6, .

- Kärger, Luise, Alexander Bernath, Florian Fritz, Siegfried Galkin, Dino Magagnato, André Oeckerath, Alexander Schön und Frank Henning. 2015. Development and validation of a CAE chain for unidirectional fibre reinforced composite components. Composite Structures 132: 350–358. doi:10.1016/j.compstruct.2015.05.047, .

- Fischer, Sebastian. 2015. Aluminium foldcores for sandwich structure application: Mechanical properties and FE-simulation. Thin-Walled Structures 90: 31–41. doi:10.1016/j.tws.2015.01.003, .

- Hoffmann, Marco, Kristian Zimmermann, Brian Bautz und Peter Middendorf. 2015. A new specimen geometry to determine the through-thickness tensile strength of composite laminates. Composites Part B: Engineering 77. doi:10.1016/j.compositesb.2015.03.020, .

- Sturm, R., P. Schatrow und Yves Klett. 2015. Multiscale Modeling Methods for Analysis of Failure Modes in Foldcore Sandwich Panels. Applied Composite Materials 22: 857–868. doi:10.1007/s10443-015-9440-9, .

2014

- Sturm, R., Yves Klett, Ch. Kindervater und H. Voggenreiter. 2014. Failure of CFRP airframe sandwich panels under crash-relevant loading conditions. Composite Structures 112: 11–21. doi:10.1016/j.compstruct.2014.02.001, .

- Gnädinger, Florian, Michael Karcher, Frank Henning und Peter Middendorf. 2014. Holistic and Consistent Design Process for Hollow Structures Based on Braided Textiles and RTM. Applied Composite Materials 21: 541–556. doi:10.1007/s10443-013-9370-3, .

- Weber, Markus J. und Peter Middendorf. 2014. Semi-analytical skin buckling of curved orthotropic grid-stiffened shells. Composite Structures 108: 616–624. doi:10.1016/j.compstruct.2013.09.031, .

- Härtel, Frank, Patrick Böhler und Peter Middendorf. 2014. An Integral Mesoscopic Material Characterization Approach. Key Engineering Materials 611-612: 280–291. doi:10.4028/www.scientific.net/KEM.611-612.280, .

- Priess, Torben, Markus Sause, Daniel Fischer und Peter Middendorf. 2014. Detection of delamination onset in laser-cut carbon fiber transverse crack tension specimens using acoustic emission. Journal of Composite Materials 49. doi:10.1177/0021998314552003, .

2013

- Böhler, Patrick, Frank Härtel und Peter Middendorf. 2013. Identification of Forming Limits for Unidirectional Carbon Textiles in Reality and Mesoscopic Simulation. Key Engineering Materials 554-557: 423–432. doi:10.4028/www.scientific.net/KEM.554-557.423, .

- Sirtautas, Justas, Anthony Pickett und P. Lépicier. 2013. A mesoscopic model for coupled drape-infusion simulation of biaxial Non-Crimp Fabric. Composites Part B: Engineering 47: 48–57. doi:10.1016/j.compositesb.2012.09.088, .

- Pickett, A. K., Andreas Erber, Tjark von Reden und Klaus Drechsler. 2013. Comparison of analytical and finite element simulation of 2D braiding. Plastics, Rubber and Composites 38: 387–395. doi:10.1179/146580109X12540995045769, .

- Galappathithi, U.I.K., Anthony Pickett, Milos Draskovic, Marc Capellaro und A.K.M. de Silva. 2013. The Effect of Ply Waviness for the Fatigue Life of Composite Wind Turbine Blades. Renewable Energy & Power Quality Journal (RE&PQJ): 1195–1199.

2012

- Birkefeld, Karin, Mirko Röder, Tjark von Reden, Martina Bulat und Klaus Drechsler. 2012. Characterization of Biaxial and Triaxial Braids: Fiber Architecture and Mechanical Properties. Applied Composite Materials 19: 259–273. doi:10.1007/s10443-011-9190-2, .

2009

- Heimbs, Sebastian, Peter Middendorf, C. Hampf, Falk Hähnel und K. Wolf. 2009. Aircraft Sandwich Structures with Folded Core under Impact Load. Composite Solutions, Aero & Space 3.

- Pickett, Anthony, Justas Sirtautas und Andreas Erber. 2009. Braiding Simulation and Prediction of Mechanical Properties. Applied Composite Materials 16: 345–364. doi:10.1007/s10443-009-9102-x, .

- Erber, Andreas und Klaus Drechsler. 2009. Torsional Performance and Damage Tolerance of Braiding Configurations. JEC Magazine 52.

- Pickett, A. K., M. R. C. Fouinneteau und Peter Middendorf. 2009. Test and Modelling of Impact on Pre-Loaded Composite Panels. Applied Composite Materials 16: 225–244. doi:10.1007/s10443-009-9089-3, .

- Heimbs, Sebastian, S. Heller, Peter Middendorf, Falk Hähnel und J. Weiße. 2009. Low velocity impact on CFRP plates with compressive preload: Test and modelling. International Journal of Impact Engineering 36. doi:10.1016/j.ijimpeng.2009.04.006, .

- Keck, Rüdiger, Wolfgang Machunze, Wolfgang Dudenhausen und Peter Middendorf. 2009. Design, analysis, and manufacturing of a carbon-fibre-reinforced polyetheretherketone slat. Proceedings of Mechanical Engineering Vol. 223 Part G: J. Aerospace Engineering 223. doi:10.1243/09544100JAERO515, .

2008

- Drechsler, Klaus, Peter Middendorf, Van Den Broucke B. und Sebastian Heimbs. 2008. Advanced Composite Materials - Technologies, Performance and Modelling. In: Course on emerging techniques for damage prediction and failure analysis of laminated composite structures, hg. von Didier Guédra-Degeorges und Pierre Ladevèze, 147–197. Toulouse: Cépaduès-éd.

2006

- Greve, L. und A. K. Pickett. 2006. Modelling damage and failure in carbon/epoxy non-crimp fabric composites including effects of fabric pre-shear. Composites Part A: Applied Science and Manufacturing 37: 1983–2001. doi:10.1016/j.compositesa.2005.12.012, .

Conference proceedings

2024

- Hügle, Sebastian, Adam J. Thompson, Micheal Pei, Stephen R. Hallett und Peter Middendorf. 2024. Modeling Of A Realistic Fiber Bundle Architecture In The Robotic Coreless Filament Winding Process. In: . TexComp-15, Leuven, Belgien.

2023

- Krischler, Ruben, Markus Blandl, Maike Kliewe, Stefan Carosella und Peter Middendorf. 2023. Comparison of Different Material Systems for Filament Winding Based on the Split-Disk Experiment and Setup of a Digital Twin. In: Proceedings of the Munich Symposium on Lightweight Design 2022, hg. von Jasper Rieser, Felix Endress, Alexander Horoschenkoff, Philipp Höfer, Tobias Dickhut, und Markus Zimmermann, 40–50. Cham: Springer International Publishing and Imprint Springer Vieweg, September. doi:10.1007/978-3-031-33758-14, .

2022

- Czichos, R., A. Miene, H. Ahlborn, D. Thal, J. Greiner, P. Middendorf und A. Herrmann. 2022. Mesoscopic modeling of braided structures by means of laser triangulation measurement and mesh superposition technique. Proceedings of 14th International Conference on Textile Composites (TexComp 14). September.

- Czichos, Ruben, Peter Middendorf und T. Bergmann. 2022. Numerical modelling of the residual burst pressure of thick composite pressure vessels after low-velocity impact loading. In: Current Perspectives and New Directions in Mechanics, Modelling and Design of Structural Systems, hg. von Alphose Zingoni, 157–158. London: CRC Press, September. doi:10.1201/9781003348450-73, .

- Wolf, Martin, Benjamin Kaiser, Sebastian Hügle, Alexander Verl und Peter Middendorf. 2022. Data Model for Adaptive Robotic Construction in Architecture. In: Procedia CIRP, 107:1035–1040. Elsevier BV. doi:10.1016/j.procir.2022.05.104, https://doi.org/10.1016%2Fj.procir.2022.05.104.

- Wolf, Martin, Benjamin Kaiser, Sebastian Hügle, Alexander Verl und Peter Middendorf. 2022. Data Model for Adaptive Robotic Construction in Architecture. In: Procedia CIRP, 107:1035–1040. Elsevier BV. doi:10.1016/j.procir.2022.05.104, https://doi.org/10.1016%2Fj.procir.2022.05.104.

2021

- Facciotto, S., A. Pickett, P. Middendorf, P. Simacek und S.G. Advani. 2021. Numerical and Experimental Study of Dual Scale Flow in RTM with Anisotropic Tow Saturation. In: . NAFEMS World Congress. Oktober.

- Sommer, Daniel, Vinod Kumar Mitruka, Tarun Kumar Mitruka und Peter Middendorf. 2021. Automation of LS-DYNA’s Material Model Driver for Generation of Training Data for Machine Learning based Material Models. In: 13th European LS-DYNA Conference 2021. Oktober.

- Springmann, M., S. Mirzaei und P. Middendorf. 2021. Printing Path Based Modeling of FFF Meso-structures for Finite Element Analysis. In: . NAFEMS World Congress. Oktober.

- Raichle, Andreas, Andreas Damm und Peter Middendorf. 2021. Data Requirements for Detecting Collision Positions on Fiber Composite Plates Using Artificial Intelligence. In: . NAFEMS World Congress. Oktober.

- Thissen, Simon und Peter Middendorf. 2021. Numerical analysis of imperfections in Miura Ori sandwich cores using isogeometric analysis. In: Proceedings of the IASS Annual Symposium; 7th International Conference on Spatial Structures. August. https://www.researchgate.net/publication/356503384_Numerical_analysis_of_imperfections_in_Miura_Ori_sandwich_cores_using_isogeometric_analysis.

- Czichos, R., Y. Bernhardt, J. Dittmann, P. Middendorf und M. Kreutzbruck. 2021. Modellierung von Mikroschäden in glasfaserverstärkten Kunststoffen. In: . Beiträge zum 27. Stuttgart Kunststoffkolloquium. Stuttgart, März.

- Czichos, R., A. Miene, H. Ahlborn, D. Thal, J. Greiner, P. Middendorf und A. Herrmann. 2021. Realistic mesoscopic modelling of braided fibre composite structures using laser triangulation. In: .

2020

- Dittmann, Jörg, M. Vinot, Peter Middendorf und Nathalie Toso. 2020. Simulation supported manufacturing of profiled composite parts with the braiding technique. In: . SCAP 2020 - Stuttgart Conference on the Automotive Production. Stuttgart, Oktober.

- Facciotto, Silvio, Daniel Sommer, A. Haufe, M. Helbig und Peter Middendorf. 2020. Modelling Defects of Unhardened Adhesives Resulting from Handling and Warpage: Viscous Fingering. In: . SCAP 2020 - Stuttgart Conference on the Automotive Production. Stuttgart, Oktober.

- Endrass, M., Simon Thissen, S. Jarka, Octeau M.-A., Palardy-Sim M., J. Barroeta Robles, L. Larsen, A. Yousefpour und M. Kupke. 2020. Towards Continous Resistance Welding for Full-Scale Aerospace Components. In: . SAMPE Europe. Oktober.

- Klett, Yves, Peter Middendorf, Fabian Muhs und Tomohiro Tachi. 2020. Comparison of Soft Curved Crease Surrogate Hinges. In: Volume 10: 44th Mechanisms. August. doi:10.1115/DETC2020-22333, .

- Klett, Yves, P. Middendorf, Fabian Muhs und T. Tomohiro. 2020. Comparison of soft curved crease surrogate hinges. In: . Intl. Design Engineering Technical Conferences and Computers and Information in Engineering Conference. St. Louis, MO, USA, August.

- Sommer, Daniel, Florian Schauwecker und P. Middendorf. 2020. A Study on the Transfer of GISSMO Material Card Parameters from 2D- to 3D-Discretization. In: . 16th International LS-DYNA Conference. Virtual Event, Juni.

2019

- Facciotto, Silvio, A. K. Pickett und P. Middendorf. 2019. Effect of infusion parameters and defects of the reinforcement on the generation of porosity in fiber reinforced composites. In: . ESI Forum Deutschland. Berlin, November.

- Ackermann, Annika C., S. Carosella, P. Middendorf und Bronwyn Fox. 2019. Einfluss der Oberflächenfunktionalisierung von Graphenpartikeln auf die Eigenschaften und die Verarbeitung von Nanokompositen. In: . Hybride Materialien - Nano goes Macro. Nuremberg, November.

- Springmann, Marlies. 2019. Verbindung lastpfad-optimierter FVK Strukturen mit additiv gefertigten Elementen. In: . AFBW AG Simulation. Denkendorf, Oktober.

- Klett, Yves, P. Middendorf, Fabian Muhs, Werner Sobek, Stefanie Weidner und Walter Haase. 2019. Exploration of Compliant Hinges in Origami-based Structures. In: . IASS Annual Symposium 2019 -- Structural Membranes 2019. Barcelona, Spain, Oktober.

- Klett, Yves, P. Middendorf, Fabian Muhs, Werner Sobek, Weidner und Walter Haase. 2019. Exploration of Compliant Hinges in Origami-based Structures. In: . IASS Symposium 2019. Barcelona, Spain, Oktober.

- Dittmann, J., Andreas Friedrichs, S. Nassen, Silvio Facciotto und P. Middendorf. 2019. Transient Dual-Phase Void Prediction in Microscopic Yarn Models With Openfoam. In: . ICCM22 - 22nd International Conference on Composite Materials. Melbourne, Australia, September.

- Czichos, Ruben, Oscar Bareiro, A. K. Pickett, P. Middendorf und T. Gries. 2019. Numerical Modelling of Biaxial Carbon Fiber Braids Considering Process Variabilities. In: . ICCM22 - 22nd International Conference on Composite Materials. Melbourne, Australia, September.

- Dittmann, Jörg, Andreas Friedrichs, Silvio Facciotto und Peter Middendorf. 2019. Dual Phase Void Prediction in Microscopic Yarn Models. In: . ICCM22 - 22nd International Conference on Composite Materials. Melbourne, Australia, August.

- Klett, Yves. 2019. Von Stricklieseln und Papierfliegern. In: . WiWeb Kolloquium 2019. Erding, August.

- Klett, Yves. 2019. When four creases meet: Technical tessellation tales. In: . IDETC-CIE 2019 International Design Engineering Technical Conferences & Computers and Information in Engineering Conference. Anaheim, USA, August.

- Middendorf, Peter. 2019. Composites 4.0: From Design to Automated Manufacturing. In: . ICCM22 - 22nd International Conference on Composite Materials. Melbourne, Australia, August.

- Oei, Marius, Yves Klett, Nadine Harder, Daniela Flemming und Oliver Sawodny. 2019. Modelling the Flow and Heat Transfer Characteristics of Perforated Foldcore Sandwich Composites for Application in Room Air Conditioning. In: . 2019 IEEE 15th International Conference on Automation Science and Engineering (CASE). Vancouver, Canada, August. doi:10.1109/COASE.2019.8842913, .

- Klett, Yves. 2019. Paper, planes and more -- Exploring the potential of origami, from aerospace to architecture. In: . Seminar at Georgia Tech. Atlanta, USA, August.

- Sachse, Ronny, Marc Jochens, Markus Ross, A. K. Pickett und P. Middendorf. 2019. Low-Velocity Impact Simulation with a Special Focus on Thick Composites. In: . ICCM22 - 22nd International Conference on Composite Materials. Melbourne, Australia, August.

- Klett, Yves und Peter Middendorf. 2019. Exploration of Plastically Annealed Lamina Emergent Origami Structures. In: . EMI Engineering Mechanics Institute Conference 2019. Pasadena, USA, Juni.

- Althammer, Florian, D. Moncayo und Peter Middendorf. 2019. Approach for Modelling Thermoplastic Generative Designed Parts. In: . 12th European LS-DYNA Conference. Koblenz, Mai.

- Schauwecker, Florian, D. Moncayo, Filipe Andrade, Markus Feucht, Markus Beck und P. Middendorf. 2019. Modeling of Bolts using the GISSMO Model for Crash Analysis. In: . 12th European LS-DYNA Conference. Koblenz, Mai.

- J. Dittmann und P. Middendorf. 2019. Permeabilitätsmessungen bei technischen Textilien und die Durchführung von Benchmarkstudien. In: . 26. Stuttgarter Kunststoffkolloquium. Stuttgart, Germany, März.

- Kretschmer, Matthias, Jason Jonkman und Po Wen Cheng. 2019. Validation of FAST.Farm considering structural loads at alpha ventus. In: . Wind Energy Science Conference 2019. Cork. doi:10.5281/zenodo.3550524, .

2018

- Neumann, Andres, Anthony Pickett und P. Middendorf. 2018. Measurement of Size Effects in Laminate Compression Specimens. In: . Conamet-Sam. Valdivia, Chile, November.

- Facciotto, Silvio, A. Pouchias, Tifkitsis K. I., Anthony Pickett, J. Stein, A. A. Skordos und C. Miguel-Giraldo. 2018. Variability propagation, process monitoring and simulation tools for predictive modelling of RTM processes. In: . 8th EASN-CEAS International Workshop. Glasgow, Scotland, September.

- Muhs, Fabian, Yves Klett und Peter Middendorf. 2018. Automated Numerical Process Chain for the Design of Folded Sandwich Cores. In: . 7th International Meeting on Origami, Science, Mathematics, and Education. Oxford, England, September.

- Fial, J., M. Harr, Patrick Böhler und Peter Middendorf. 2018. Automated wet compression moulding of load-path optimized TFP preforms with low cycle times. In: . 13th international conference on textile composites (Texcomp). Milan, Italy, September.

- Klett, Yves. 2018. PALEO: Plastically Annealed Lamina Emergent Origami. In: . ASME 2018 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. Quebec, Canada, August.

- Facciotto, Silvio, Anthony Pickett, Lingua A., Jorge Ignacio López Palomarez und Peter Middendorf. 2018. Effect of Fabric Deformation and Flow Velocity on Generation of Porosity in Infusion Processes. In: . FPCM - 14th International Conference on Flow Processes in Composite Materials. Lule\aa,~Sweden, Juni.

- Draskovic, Milos, Anthony K. Pickett und P. Middendorf. 2018. In-Situ Image Processing of Fatigue Damaged Cross-Ply Laminates Coupled With Simulation to Predict Residual Strength Degradation. In: . ECCM 18 - 18th European Conference on Composite Materials. Athens, Greece, Juni.

- Engelfried, Mathias, Lyane Antonin Mavoungou, Ilja Verspohl, Patrick Böhler und Peter Middendorf. 2018. Generating Representative Volume Elements of Yarns with Non-Circular Filaments‘ Cross-Sections. In: . FPCM - 14th International Conference on Flow Processes in Composite Materials. Lule\aa, Sweden, Juni.

- Dittmann, J., Patrick Böhler, M. Vinot, C. Liebold, F. Fritz, A. Pau, N. Dölle, u. a. 2018. Der Digitale Prototyp. In: . Technologietag Hybrider Leichtbau. Stuttgart, Juni.

- Schwingel, Johannes, J. Wellekötter, S. Baz, P. Middendorf, C. Bonten und Götz Gresser. 2018. Resource and Energy Efficient Manufacturing of Automotive Lightweight Parts Made of Recycled Material. In: . ECCM 18 - 18th European Conference on Composite Materials. Athens, Greece, Juni.

- Schauwecker, Florian, D. Moncayo, Markus Beck und P. Middendorf. 2018. Investigation of the Failure Behavior of Bolted Connections under Crash Loads and a Novel Adaption to an Enhanced Abstracted Bolt Model. In: . 15th International LS-DYNA Conference. Detroit, USA, Juni.

- Diermann, Verena, P. Middendorf, Boese C. und Pascal Schlaak. 2018. Towards an Automatic Evaluation of a Car Floor Module in a Pole Crash Load Case. In: . 15th International LS-DYNA Conference. Detroit, USA, Juni.

- Fial, J., J. Hüttl, P. Middendorf und Frank Henning. 2018. Ganzheitliche Untersuchung der Nasspresstechnologie anhand ausgewählter Prozess- und Simulationsrouten. In: . 5. Technologietag hybrider Leichtbau. Stuttgart, Juni.

- Klett, Yves und Peter Middendorf. 2018. BiSKiTs: Bistable Kirigami Tessellations. In: . EMI Engineering Mechanics Institute Conference 2018. Boston, USA, Mai.

- Sommer, Daniel, B. Bender, F. Eidmann und Peter Middendorf. 2018. Manufacturing of hybrid steel-FRP specimens for the characterization of material properties. In: . 29th SICOMP Conference on Manufacturing and Design of Composites. Lule\aa,~Sweden, Mai.

- Klett, Yves. 2018. Kleine Falten, große Wirkung: Kostengünstige und leistungsfähige Leichtbaulösungen. In: . 2. Kongress Innovation+: Papier, Textil & Folie. Regensburg, Februar.

- Klett, Yves. 2018. Kostengünstige und leistungsfähige Lösungen für multifunktionalen Leichtbau. In: . innovation+: papier, textil & folie. Regensburg, Januar.

2017

- Draskovic, Milos, A. K. Pickett, Stefan Carosella, Luise Kärger, Frank Henning und Peter Middendorf. 2017. Accelerated Residual Strength After Fatigue Testing Using In-Situ Image Processing for Damage Detection. In: . SAMPE Conference 2017. Stuttgart, November.

- Klett, Yves. 2017. Overview of Mechanical Properties of Foldcore-based Sandwich Structures. In: . The Second International Workshop on Origami Engineering, Tianjin, China. Tianjin, China, November.

- Muhs, Fabian und Peter Middendorf. 2017. Mechanical Performance of Curved Sandwich Foldcores. In: . SAMPE Conference 2017. Stuttgart, November.

- Dittmann, Jörg und Peter Middendorf. 2017. Numerische Permeabilitätsvorhersage von textilen RTM-Preforms. In: . CC Austria, RTM - Next Steps. Friedrichshafen, September.

- Klett, Yves. 2017. Kleine Knicke, große Wirkung -- faltungsbasierte Sandwichkerne. In: . 2. Bremer Faserverbundtage. Bremen, September.

- Klett, Yves, Carla Zeger und Peter Middendorf. 2017. Experimental Characterization of Pressure Loss Caused by Flow Through Foldcore Sandwich Structures. In: . ASME 2017 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. Cleveland, OH, USA, September. doi:10.1115/DETC2017-67890, .

- Dittmann, Jörg, S. Hügle, P. Seif, Kaufmann L. und Peter Middendorf. 2017. Permeability Prediction Using Porous Yarns in a Dual-Scale Simulation with Openfoam. In: . ICCM21 - 21st International Conference on Composite Materials. Xi’an, China, August.

- Wellekötter, Jochen, Stephan Baz, Johannes Schwingel, Götz Theo Gresser, Peter Middendorf und Christian Bonten. 2017. Recycling of composites -- A new approach minimizes downgrading. In: . EUROPE/AFRICA CONFERENCE DRESDEN 2017 -- POLYMER PROCESSING SOCIETY PPS. Dresden, Germany, August. doi:10.1063/1.5084841, .

- Klett, Yves. 2017. Experimental Characterization of Pressure Loss Caused by Flow Through Foldcore Sandwich Structures. In: . ASME 2017 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. Cleveland, OH, USA, August.

- Sommer, Daniel und Iskender Silak. 2017. Untersuchung von hybriden Klebeverbindungen während des Aushärteprozesses in einem gläsernen Ofen. In: . CCeV Engineering/Klebtechnik/NDE. Augsburg, Juli.

- Klett, Yves, Peter Middendorf, Werner Sobek, Walter Haase und Michael Heidingsfeld. 2017. Potential of origami-based shell elements as next-generation envelope components. In: . IEEE International Conference on Advanced Intelligent Mechatronics (AIM). Munich, Juli. doi:10.1109/AIM.2017.8014135, .

- Schwingel, Johannes, S. Baz, J. Wellekötter und Stefan Carosella. 2017. Resource and Energy Efficient Manufacturing of Automotive Lightweight Parts Made of Recycled Material. In: . BW Forschungstag 2017. Stuttgart, Juni.

- Liebold, C., A. Haufe, M. Vinot, J. Dittmann, Patrick Böhler, H. Finckh und P. Middendorf. 2017. The Digital Prototype as Part of Envyo - Developent History and Applications within the ARENA2036 Environment. In: . 11th European LS-DYNA Conference. Salzburg, Austria, Mai.

- Böhler, Patrick, Jörg Dittmann, D. Michaelis, Peter Middendorf und C. Liebold. 2017. Manufacturing Simulation as Part of the Digital Prototype. In: . 11th European LS-DYNA Conference 2017. Salzburg, Austria, Mai.

- Engelfried, Mathias, J. Fial, Manuel Tartler, Patrick Böhler, D. Hägele und Peter Middendorf. 2017. A Mesoscopic Approach for Draping Simulation of Preforms Manufactured by Direct Fibre Placement. In: . 20th International ESAFORM Conference on Material Forming. Dublin, Ireland, April.

- Facciotto, Silvio, Jörg Dittmann, A. K. Pickett und Peter Middendorf. 2017. Characterization and Modelling of Local Compaction Effect on Permeability in Infusion Processes. In: . 8th International Conference on Composites Testing and Model Identification. Leuven, Belgium, April.

- Draskovic, Milos, A. K. Pickett und Peter Middendorf. 2017. Influence of Ply Waviness on the Residual Strength After Fatigue in GFRP - Comparison of Localized and Uniform Defects. In: . 8th International Conference on Composites Testing and Model Identification. Leuven, Belgium, April.

- Neumann, Andres, A. K. Pickett und Peter Middendorf. 2017. Finite Element and Experimental Stress Analysis of Laminated Composite Compression Specimens. In: . 8th International Conference on Composites Testing and Model Identification. Leuven, Belgium, April.

- Wellekötter, J., C. Bonten, S. Baz, T. Gresser, Johannes Schwingel und Peter Middendorf. 2017. Resource-Efficient Lightweight Design Due to New Recycling Concept. In: . 25. Stuttgarter Kunststoffkolloquium. Stuttgart, März.

- Dittmann, Jörg, F. Dollinger, Kaufmann L. und Peter Middendorf. 2017. Numerical Permeability Prediction with OpenFOAM. In: . 25. Stuttgarter Kunststoffkolloquium. Stuttgart, März.

2016

- Schwingel, Johannes. 2016. Resource and Energy Efficient Manufacturing of Automotive Lightweight Parts Made of Recycled Material. In: . International Textile Conference 2016 (Aachen-Dresden-Denkendorf). Dresden, November.

- Dittmann, Jörg, Patrick Böhler, D. Michaelis und Peter Middendorf. 2016. DigitPro -- Aufbau eines digitalen Prototyps für den industriellen Großeinsatz 4.0. In: . NAFEMS Seminar - Simulation von Composites -- Bereit für Industrie 4.0. Hamburg, Oktober.

- Dittmann, Jörg und Peter Middendorf. 2016. ARENA2036 -- Above-and-Beyond. In: . LS-Dyna User Forum. Bamberg, Oktober.

- Middendorf, Peter. 2016. DigitPro: Ganzheitlicher digitaler Prototyp für industriellen FVK-Leichtbau. In: . Forel Kolloquium. Oktober.

- Klett, Yves, Fabian Muhs und Peter Middendorf. 2016. Behavior of Congruent Tessellation Stacks Under Torsional Loading. In: . ASME 2016 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference (IDETC/CIE2016). Charlotte, USA, August.

- Dittmann, Jörg, S. Hügle und Peter Middendorf. 2016. Numerical 3D Permeability Prediction Using Computational Fluid Dynamics Techniques. In: . FPCM - 13th Internation Conference on Flow Processes in Composite Materials. Kyoto, Japan, Juli.

- Sachse, Ronny, A. K. Pickett, M. Gnädinger und Peter Middendorf. 2016. Mechanisms to Arrest a Crack in the Adhesive Bondline of Fatigue Loaded CFRP-Joints Using a Rivetless Nutplate Joint. In: . ECCM17 17th European Conference on Composite Materials. Munich, Juni.

- Dittmann, Jörg und Peter Middendorf. 2016. DigitPro - Ganzheitlicher digitaler Prototyp im Leichtbau für die Großserienproduktion. In: . Fachtagung Wissenschaft und Wirtschaft nachhaltig vernetzen. Berlin, Juni.

- Engelfried, Mathias, Tomas Nosek, Frieder Heieck, Patrick Böhler und Peter Middendorf. 2016. Mesoscopic draping simulation of out-of-autoclave prepregs and experimental validation. In: . ECCM17 17th European Conference on Composite Materials. Munich, Juni.

- Muhs, Fabian, Yves Klett und Peter Middendorf. 2016. Influence of Geometry and Base Material on the Compressive Properties of Foldcores. In: . ECCM17 17th European Conference on Composite Materials. Munich, Juni.

- Dittmann, Jörg, D. Michaelis, Patrick Böhler und Peter Middendorf. 2016. DigitPro - Validating The Link Between Braiding Simulation, Infiltration and Mechanical Testing. In: . ECCM17 17th European Conference on Composite Materials. Munich, Juni.

- Zink, Dennis, C. Awe und Peter Middendorf. 2016. Automated Design Approach and Potential Assessment of Composite Structures: Fast Analytical Engineering Tool for Multiple Load Cases. In: . ECCM17 17th European Conference on Composite Materials. Munich, Juni.

- Vinot, M., M. Holzapfel, D. Michaelis, Jörg Dittmann, Patrick Böhler, Peter Middendorf und C. Liebold. 2016. Numerische Prozesskette für die Auslegung von geflochtenen Fahrzeugkomponenten - Nutzen und Herausforderungen. In: . Symposium Faszination Hybrider Leichtbau. Wolfsburg, Mai.

- Middendorf, Peter, D. Michaelis, Patrick Böhler, Jörg Dittmann und Frieder Heieck. 2016. ARENA2036 - DigitPro: Development of a Virtual Process Chain. In: . 16th Stuttgart International Symposium on Automotive and Engine Technology. Stuttgart, März.

2015

- Adebahr, W., Ronny Sachse, Peter Middendorf und Marc Kreutzbruck. 2015. Crack growth monitoring at CFRP adhesive bondings. In: . Polymer Processing Society Conference 2015. Graz, Austria, Oktober. doi:10.1063/1.4965563, .

- Fuhr, Jan-Philipp und Peter Middendorf. 2015. Validierung der virtuellen Auslegungsprozesskette für schichtbasierte Faserverbundstrukturen. In: . ESI DACH Forum. Bamberg, Oktober.

- Böhler, Patrick und Peter Middendorf. 2015. Mesoskopisches Drapieren - Simulation und Vailidierung. In: . LBZ-Tagung. Pfinztal, Oktober.

- Klett, Yves und Peter Middendorf. 2015. Kinematic analysis of congruent multilayer tessellations. In: . ASME International Design Engineering Technical Conferences. Boston, USA, August.

- Gabrielli, R. A., J. Seelmann, A. Großmann, G. Herdrich, S. Fasoulas, P. Schnauffer, Peter Middendorf, M. Fateri und A. Gebhardt. 2015. System Architecture of a Lunar Industry Plant Using Regolith. In: . 30th ISTS. Kobe, USA, Juli.

- Gabrielli, R. A., J. Mathies, A. Großmann, G. Herdrich, S. Fasoulas, P. Schnauffer, Peter Middendorf, M. Fateri und A. Gebhardt. 2015. Space Propulsion Considerations for a Lunar Take Off Industry Based on Regolith. In: . 30th ISTS. Kobe, USA, Juli.

- Großmann, A., R. A. Gabrielli, G. Herdrich, S. Fasoulas, P. Schnauffer, Peter Middendorf, M. Fateri und A. Gebhardt. 2015. Overview of the MultiRob 3D Lunar Industrial Development Project. In: . 30th ISTS. Kobe, USA, Juli.

- Weber, Markus J. und Peter Middendorf. 2015. Semi-analytical panel buckling of cylindrical composite grid-stiffened structures comprising discrete stiffener formulations. In: . 18th International Conference on Composite Structures (ICCS18). Lisbon, Portugal, Juli.

- Sachse, Ronny, A. K. Pickett, W. Adebahr, M. Klein, M. Käß und Peter Middendorf. 2015. Experimental investigation of mechanical fasteners regarding their influence on crack growth in adhesively bonded CFRP-joints subjected to fatigue loading. In: . in 20th Internactional Conference on Composite Materials. Copenhagen, Juli.

- Gizik, Daniel, Christian Metzner und Peter Middendorf. 2015. First Study on using Heavy Tow Fibers for Textile Preform Processes in the Aerospace Industry. In: . ICCM20 - 20th International Conference on Composite Materials. Copenhagen, Denmark, Juli.

- Böhler, Patrick, Stefan Carosella, C. Götz und Peter Middendorf. 2015. Reverse Draping - oder - Woher kommen Fasergerechte Ablagepfade für den TFP-Prozess. In: . Compoform 2015. Munich, Mai.

- Weber, Markus J. und Peter Middendorf. 2015. Semi-analytical global and panel buckling of composite grid-stiffened cylindrical shells. In: . 3rd International Conference on Buckling and Postbuckling Behaviour of Composite Laminated Shell Structures. Braunschweig, März. doi:10.13140/RG.2.1.3744.7200, .

- Dittmann, Jörg, A. Neu und Peter Middendorf. 2015. Permeabilitätsbestimmung für die optimierte Herstellung von endlosfaserverstärkten Kunststoffen. In: . 24. Stuttgarter Kunststoffkolloquium. Stuttgart, Februar.

- Dittmann, Jörg. 2015. Permeabilitätsbestimmung für die optimierte Herstellung von Faser-Kunststoff-Verbunden. In: . 24. Stuttgarter Kunststoffkolloquium. Stuttgart, Februar.

- Fey, P., D. Michaelis, Peter Middendorf, G. Busse und Marc Kreutzbruck. 2015. Charakterisierung anisotroper Schädigung in CFK mittels Akustischer Doppelbrechung. In: . 24. Stuttgarter Kunststoffkolloquium. Stuttgart, Februar.

- Adebahr, W., M. Rahammer, Ronny Sachse, S. Gröninger, M. Käß, Marc Kreutzbruck und G. Busse. 2015. Crack growth monitoring at CFK adhesive bondings. In: . 24. Stuttgarter Kunststoffkolloquium. Stuttgart, Februar.

- Fuhr, Jan-Philipp und Peter Middendorf. 2015. From draping to fracture - Tool chain validation for ply-based composite structures. In: . Composites Virtual Prototyping Expert Seminar. Stuttgart, Januar.

- Sachse, Ronny, A. K. Pickett, M. Käß und Peter Middendorf. 2015. Numerical Simulation of Fatigue Crack Growth in the Adhesve Bondline of Hybrid CFRP Joints. In: . COMPOSITES 2015. Bristol.

- Middendorf, Peter, T. Sommer-Dittrich, Patrick Böhler, Jörg Dittmann, D. Michaelis, Frieder Heieck und Stefan Zuleger. 2015. Forschungscampus ARENA2036 - Leichtbau durch Funktionsintegration und Aufbau einer digitalen Prozesskette. In: . ATZ Tagung. Stuttgart.

- Dittmann, Jörg. 2015. Permeabilitätsbestimmung und der Weg zu aussagekräftigen Füllsimulationen. In: . AFBW AG Simulation. Fellbach.

- Middendorf, Peter, Patrick Böhler, Jörg Dittmann, D. Michaelis und Frieder Heieck. 2015. DigitPro - Holistic digital prototype for lightweight design in large-scale production. In: . JEC Singapore. Singapore.

- Dittmann, Jörg, Patrick Böhler, D. Michaelis, M. Vinot, C. Liebold, Florian Fritz, H. Finckh und Peter Middendorf. 2015. DigitPro - Digital Prototype Build-up Using the Example of a Braided Structure. In: . 2. International Merge Technologies Conference. Chemnitz.

2014

- Kärger, Luise, Patrick Böhler, Dino Magagnato, S. Galkin und Frank Henning. 2014. Virtuelle Prozesskette für Bauteile aus Hochleistungsfaserverbund. In: . FCC2014. Augsburg, November.

- Fuhr, Jan-Philipp, Patrick Böhler, Frieder Heieck, A. Miene und Peter Middendorf. 2014. Optische Preformanalyse zur 3D-Validierung der Drapier- und Flechtsimulation. In: . FCC2014. Augsburg, November.

- Fuhr, Jan-Philipp, N. Feindler und Peter Middendorf. 2014. Virtuelle Bewertung von Drapiereinflüssen auf die Steifigkeit und Festigkeit von schichtbasierten Faserverbundstrukturen. In: . NAFEMS Seminar. Leipzig, Oktober.

- Kärger, Luise, Florian Fritz, Dino Magagnato, S. Galkin, Alexander Schön, André Oeckerath, K. Wolf und Frank Henning. 2014. Development Stage and Application of a Virtual Process Chain for RTM Components. In: . Proceedings NAFEMS Seminar Simulation of Composites A Closed Process Chain. Leipzig, Oktober.

- Klett, Yves und Peter Middendorf. 2014. Kinematic exploration of 1-DOF origami mechanisms. In: . Proceedings of the the 16th International Conference on Geometry and Graphics. Innsbruck, Austria, August.

- Dittmann, Jörg. 2014. Permeability determination of resistive welded carbon fabrics. In: . FPCM. Enschede, Juli.

- Middendorf, Peter. 2014. ARENA2036 - Lightweight design and flexible production for next generation automobiles. In: . ICPC Konferenz. Munich, Juni.

- Fuhr, Jan-Philipp, J. Baumann, Frank Härtel, N. Feindler und Peter Middendorf. 2014. Effects of in-plane waviness on the properties of carbon composites - experimental and numerical analysis. In: . 6th International Conference on Composites Testing and Model Identification. Aalborg, Denmark, April.

- Fuhr, Jan-Philipp, N. Feindler und Peter Middendorf. 2014. Berücksichtigung von Fertigungseinflüssen in der Strukturauslegung von schichtbasierten Faserverbundwerkstoffen. In: . SAMPESymposium Deutschland 2014. Stuttgart, Februar.

- Böhler, Patrick, Frank Härtel und Peter Middendorf. 2014. Mesoskopisches Drapieren: Simulation und Validierung. In: . SAMPESymposium Deutschland 2014. Stuttgart, Februar.

2013

- Middendorf, Peter und Klaus Drechsler. 2013. Networks and Private Public Partnerships for R&D on Automotive Composites. In: . IQPC Automotive Composites. Köln, Dezember.

- Böhler, Patrick, Frank Härtel, A. K. Pickett und Peter Middendorf. 2013. Mesoskopischer Ansatz für die Drapiersimulation von unidirektionalen vernähten Textilien. In: . ESI DACH Forum. Wiesbaden, November.

- Weber, Markus J. und Peter Middendorf. 2013. Weight estimation of composite grid--stiffened fuselage structures critical to skin buckling. In: . 3rd EASN Association International Workshop on Aerostructures. Milano, Italy, Oktober.

- Böhler, Patrick, Frank Härtel und Peter Middendorf. 2013. Drapieren: Simulation und Verifikation. In: . CCeV. Meitingen, Oktober.

- Klett, Yves. 2013. Realtime rigid folding algorithm for quadrilateral- based 1-DOF tessellations. In: . ASME International Design Engineering Technical Conferences. Portland, USA, August.

- Kärger, Luise, Dino Magagnato, Alexander Schön, Patrick Böhler, Sebastian Fischer, Florian Fritz und Frank Henning. 2013. Aufbau einer durchgängigen CAE-Kette durch Verknüpfung von Drapier-, Formfüll- und Struktursimulation zur ganzheitlichen Bewertung von Bauteilen aus Hochleistungsfaserverbunden. In: . DGM Tagung Verbundwerkstoffe / Werkstoffverbunde 2013. Karlsruhe, Juli.

- Weber und Peter Middendorf. 2013. Semi-analytical skin buckling of curved orthotropic grid-stiffened shells. In: . Proceedings of ICCS17. Porto, Portugal, Juni.

- Middendorf, Peter. 2013. Potenzial und Einsatzgebiete von FKV für Leichtbauanwendungen. In: . 23. Stuttgarter Kunststoff Kolloquium. Stuttgart, März.

- Sirtautas, Justas und A. K. Pickett. 2013. Fabric permeability testing and their use in infusion simulation. In: . CompTest. Aalborg.

- Pickett, A. K., Justas Sirtautas und Masseria. 2013. Challenges of VARI process simulation: materials testing and simulation approaches. In: . CCeV. Augsburg.

- Pickett, A. K., Justas Sirtautas und Masseria. 2013. Resin infusion simulation for large structural composite parts. In: . TexComp-11. Leuven.

- Kärger, Luise, Alexander Schön, Florian Fritz, Patrick Böhler, Dino Magagnato, Sebastian Fischer und Frank Henning. 2013. Virtual Process Chain for an integrated assessment of high-performance composite structures. In: . NAFEMS World Congress. Salzburg, Austria.

- Galappathithi, U.I.K., A. K. Pickett, Milos Draskovic, Marc Capellaro und De Silva. A. K. M. 2013. The Effect of Ply Waviness for the Fatigue Life of Composite Wind Turbine Blades. In: . ICREPQ 13 (RE&PQJ). Bilbao.

- Draskovic, Milos, U.I.K. Galappathithi, A. K. Pickett, Marc Capellaro und Peter Middendorf. 2013. Influence of ply waviness on residual strength and fatigue degradation of composite wind turbine blades. In: . ICCM19. Montreal.

- Böhler, Patrick, D. Michaelis, Frieder Heieck und Peter Middendorf. 2013. Numerical prediction and experimental validation of triaxially braided fibre architecture on curved mandrels. In: . TexComp-11. Leuven.

- Pickett, A. K., Justas Sirtautas und Masseria. 2013. Process and challenges for resin infusion simulation of large structural composite parts. In: . CCeV. Stuttgart.

2012

- Liebau, van Campen, T. Sommer-Dittrich und Peter Middendorf. 2012. On the Effect of Draping Strategy on FE-Based Draping Simulation of Basic and Complex 3D Geometries for Automated Preforming. In: . 3rd Aircraft Structural Design Conference. Delft, Oktober.

- Liebau, van Campen, T. Sommer-Dittrich, Dölle und Peter Middendorf. 2012. An Approach for Investigating the complexity of an Automated Draping Process Using the Finite-Element Method. In: . European Congress on Computational Methods in Applied Sciences and Engineering (ECCOMAS 2012). Wien, September.

- Klett, Yves. 2012. Isometrically folded structures in near net shape core applications. In: . ICSS10 - International Conference on Sandwich Structure. s, August.

- Middendorf, Peter, Sebastian Jäger und Prowe. 2012. Damage Tolerance of CFRP Airframe Structures: Criteria and Concepts. In: . DLR Bauweisen Kolloquium. Stuttgart, Juni.

- Middendorf, Peter und Karin Birkefeld. 2012. Entwicklungstrends in der Faserverbund-Simulation. In: . Fachkongress Composite Simulation. Fellbach, Februar.

- Liebau, van Campen, T. Sommer-Dittrich und Peter Middendorf. 2012. User- and Process-Defined Benchmark of Kinematic and FE-Draping Codes and Integration into the CAx Process Chain. In: . NAFEMS European Conference Multiphysics Simulation. Frankfurt.

- Birkefeld, Karin. 2012. Analysis and Process Simulation of braided structures. In: . EUCOMAS. Zürich.

- Birkefeld, Karin und Peter Middendorf. 2012. Optimization of Braided Structures With a Genetic Algorithm Considering Production Aspects. In: . SETEC 12. Lucerne.

- Birkefeld, Karin, Tjark von Reden und Peter Middendorf. 2012. Material Quality of Braided Fuselage Profiles. In: . AIAA SDM Conference. Honolulu.

- Böhler, Patrick, Bouc, Holger Ahlborn und Peter Middendorf. 2012. Innovative joining of aircraft profiles with braided holes. In: . ECCM 15. Venedig.

2011

- Leutza, Kluepfelb, Dumontb, Hinterhoelzla, Klaus Drechsler und Christian Weimer. 2011. FE-Simulation of the Diaphragm Draping Process for NCF on a Macro-Scale Level. In: . 14th International ESAFORM Conference on Material Forming ESAFORM. Belfast.

- Bender, Fischer und Klaus Drechsler. 2011. Optimizing a Foldcore concerning density specific stiffness properties. In: . SEICO. Paris.

- Pickett, A. K. und Karin Birkefeld. 2011. Analysis and process simulation of textile structures. In: . SAMPE Technical Conference. Zürich.

- Fischer und Klaus Drechsler. 2011. Aluminium Faltkerne für den Einsatz in Sandwichstrukturen. In: . Landshuter Leichtbau-Colloquium. Landshut.

- Mildner, Dölle, Klaus Drechsler und Bjekovic. 2011. Influence of reinforced metal structures using fibre reinforced plastics. In: . SAMPE EUROPE 32nd International Technical Conference. Paris.

- Werchner, Havar und Klaus Drechsler. 2011. Influence of design and loading on the mechanical behaviour of thick composite lugs. In: . DGLR Kongress. Bremen.

- Feindler, N., Jan-Philipp Fuhr, Patrick Böhler, Klaus Drechsler und J. Döll. 2011. Simulation und Dimensionierung von energieabsorbierenden Faserverbundstrukturen für automobile Anwendungen. In: . NWC11 NAFEMS 2011.

- Feindler, N., J. Döll und Klaus Drechsler. 2011. CFK in automobilen Crashstrukturen: Anforderungen, Dimensionierung und Simulation. In: . ATZlive. Werkstoffe im Automobilbau.

2010

- Drechsler, Klaus und Yves Klett. 2010. Technical Tessellations - Hidden Beauties. In: . 5OSME Conference. Singapore.

- Grzeschik, Marc und Klaus Drechsler. 2010. Experimental studies on folded cores. In: . 9th International Conference on Sandwich Structures. Los Angeles.

- Kehrle, R. 2010. Leichtbauplatten mit Foldcore Kernen. In: . Möbelleichtbau-Symposium. Lemgo.

- Werchner, Havar und Klaus Drechsler. 2010. Design Guidelines and Analysis Methods for Composite Load Introduction Structures. In: . Simulia Konferenz. Heidelberg.

- Kehrle, R. 2010. Leichtbausandwichwerkstoffe. In: . Yachtbau Symposium. Hamburg.

- Birkefeld, Karin, A. K. Pickett, Volker Witzel und Klaus Drechsler. 2010. Procedures for optimisation of structural composite aircraft profiles considering manufacturing constraints. In: . 3rd EUCOMAS. Berlin.

- Beilstein, Klaus Drechsler und S. Rudolph. 2010. Gewichtsabschätzungen von geklebten und geschweißten Strukturverbindungen im Flugzeugvorentwurf. In: . DLRK. Hamburg.

- Rudolph, S., Jan-Philipp Fuhr und Beilstein. 2010. A validation method using design languages for weight approximation formulae in the early aircraft design phase. In: . EUCOMAS. Mannheim.

- Kehrle, R. 2010. Forschung und Entwicklung von Faserverbund- und Sandwichleichtbau im Flugzeug- und Automobilbau. In: . VDI Stuttgart. Germany.

- Birkefeld, Karin, Andreas Erber und Klaus Drechsler. 2010. Virtual Design Process for Braided Drive Shafts. In: . SAMPE SEICO Conference. Paris.

- Drechsler, Klaus. 2010. Funktionsintegrierter Leichtbau. In: . 9. Symposium Material Innovativ. Augsburg.

2009

- Kehrle, R. 2009. Chancen durch Faserverbundwersktoffe im Anlagenbau - Potenziale und Risiken. In: . CCe.V. Augsburg. Germany.

- Fischer, Marc Grzeschik und Klaus Drechsler. 2009. Potential of high performance foldcores made out of Peek. In: . SETEC Europe. Bristol.

- Kehrle, R. 2009. Sandwichbauweisen in der Luftfahrt. In: . Leichtbaukolloquium. Landshut.

- Grave, Karin Birkefeld, Tjark von Reden, Klaus Drechsler, Yordan Kyosev und Rathjens. 2009. Simulation of 3D overbraiding - Solutions and Challenges. In: . Second World Conference on 3D Fabrics and their Applications. Greenville.

- Klett, Yves, Klaus Drechsler, R. Kehrle und Fach. 2009. Cutting Edge Cores: Multifunktionale Faltkernstrukturen. In: . 4. Landshuter Leichtbau-Colloquium. Landshut.

- Klett, Yves und Klaus Drechsler. 2009. Cutting edge cores: Multi- functional Core Structures. In: . DGLR Jahrestagung.

- Kehrle, R. 2009. Faserverbundwerkstoffe. In: . IHK. Reutlingen.

- Johnson, Alastair, Sebastian Kilchert, Fischer und R. Kehrle. 2009. New structural composite core materials. In: . Composites. Gold Coast.

- Fischer, Marc Grzeschik und Klaus Drechsler. 2009. Experimental and numerical parameter study of foldcores. In: . Vortrag auf der Sampe Europe Technical Conference. Bristol.

- George, A., Klaus Drechsler und Holmberg. 2009. The Permeability of Tackified, Stitched, and Braided Carbon Fiber Textiles: Experi-mental Characterization and Design Modeling. In: . SAMPE. Baltimore.

- George, A., Klaus Drechsler und Holmberg. 2009. The Permeability of Carbon Fiber Preforming Materials: Sensitivity to Fabric Geometry. In: . 20th Annual International SICOMP Conference. Pite\aa.

- Drechsler, Klaus. 2009. Leichtbaupotential von Faserverbundwerkstoffen im Maschinenbau. In: . IHK Innovationspodium. Augsburg.

2008

- Fischer und Klaus Drechsler. 2008. Aluminium foldcores for sandwich structure application. In: . CompTest.

- Fischer, Klaus Drechsler, Sebastian Kilchert und Alastair Johnson. 2008. Mechanical tests for foldcore base material properties. In: . CompTest.

- Fischer und Klaus Drechsler. 2008. Aluminium Foldcores for Sandwich Structure Application. Cellular Metals for Structural and Functional Applications. In: . CELLMET.

- Klett, Yves und Klaus Drechsler. 2008. Cutting edge cores: Aerospace and origami. In: . 9th International Mathematica Symposium. Maastricht.

- Klett, Yves und Klaus Drechsler. 2008. Cutting-Edge Cores - Origami Meets Aerospace. In: . International Mathematica User Conference. Champaign.

2007

- Stüve, Gries, Klaus Drechsler, Volker Witzel, Miravete und Tolosana. 2007. Simulation of braiding technology along the complete process chain. In: . International European SAMPE Conference. Paris.

- Beilstein und Klaus Drechsler. 2007. A methodology of weight prediction for joints in aircraft design. In: . SAWE. Madrid.

- Klett, Yves und Klaus Drechsler. 2007. Design of Multifunctional Folded Core Structures for Aerospace Sandwich Applications. In: . 1st CEAS European Air and Space Conference.

- Moncayo, Wagner und Klaus Drechsler. 2007. Numerical Simulation of Low Velocity Impact Delamination in Composite Materials. In: . CanCom. Montreal.

- Klett, Yves, R. Kehrle, Klaus Drechsler und Stefan Carosella. 2007. High Tech Origami. In: . Composite Days. Innsbruck.

2006

- Drechsler, Klaus. 2006. Origami-like Sandwich Structures for Aerospace Applications. In: . SAMPE International Conference. Long Beach.

- Drechsler, Klaus, R. Kehrle, Yves Klett und E. Thorsteinsson. 2006. Faltwabenkerne für multifunktionale Leichtbaustrukturen. In: . 2nd MATERIALICA Composites Congress Composites in Automotive Aerospace. München.

- Drechsler, Klaus, R. Kehrle und Kolax. 2006. Folded Core Sandwich Structures for advanced next generation fuselage concepts. In: . SAMPE Europe Technical Conference. Toulouse.

- Drechsler, Klaus. 2006. Leichtbau in Natur und Technik. In: . HIN Kolloquium. Neckarsulm.

2005

- Drechsler, Klaus. 2005. Neueste Entwicklungen der Faserverbundtechnologie für den Flugzeug- und Automobilbau. In: . Vortrag VDI Arbeitskreis Produktionstechnik. Stuttgart.

- Kehrle, R. und Pfaff. 2005. Mechanische Eigenschaften neuartiger Sandwichkerne. In: . 6. Nationales Symposium SAMPE. Stuttgart.

- Kehrle, R. und Klaus Drechsler. 2005. Manufacturing and performance of folded honeycomb structures. In: . SAMPE. Long Beach.

- Drechsler, Klaus. 2005. Leichtbau im Fahrzeug. In: . Euroforum-Konferenz. München.

- Kehrle, R. und Klaus Drechsler. 2005. Manufacturing, Simulation and performance of sandwich structures with folded core. In: . 25th International SAMPE Conference. Paris.

- Drechsler, Klaus. 2005. Origami and aerospace - a new approach for sandwich structures. In: . Keynote presentation at International SAMPE Conference. Tokyo.

Head of Department

Peter Middendorf

Prof. Dr.-Ing.Head of the departments Lightweight Design and Simulation and Manufacturing Technologies

Michael May

Dr.Deputy Head of Department Lightweight Design and Simulation