In the process simulation, individual steps of the FVW manufacturing processes such as draping, infiltrating, braiding as well as winding, pultrusion, wet pressing, APP and AM processes are performed virtually. With increasing digitization, robot movements and production machines can be monitored and controlled from the process simulation via CAM interfaces. Sensors integrated in the component ensure that process variables can be recorded, logged, validated and fed back to the respective production unit during manufacturing. The aim of the predictive process simulation is therefore to generate process variables and boundary conditions for real life production and to obtain an optimal machine setup in advance, taking into account real material behavior.

Research topics

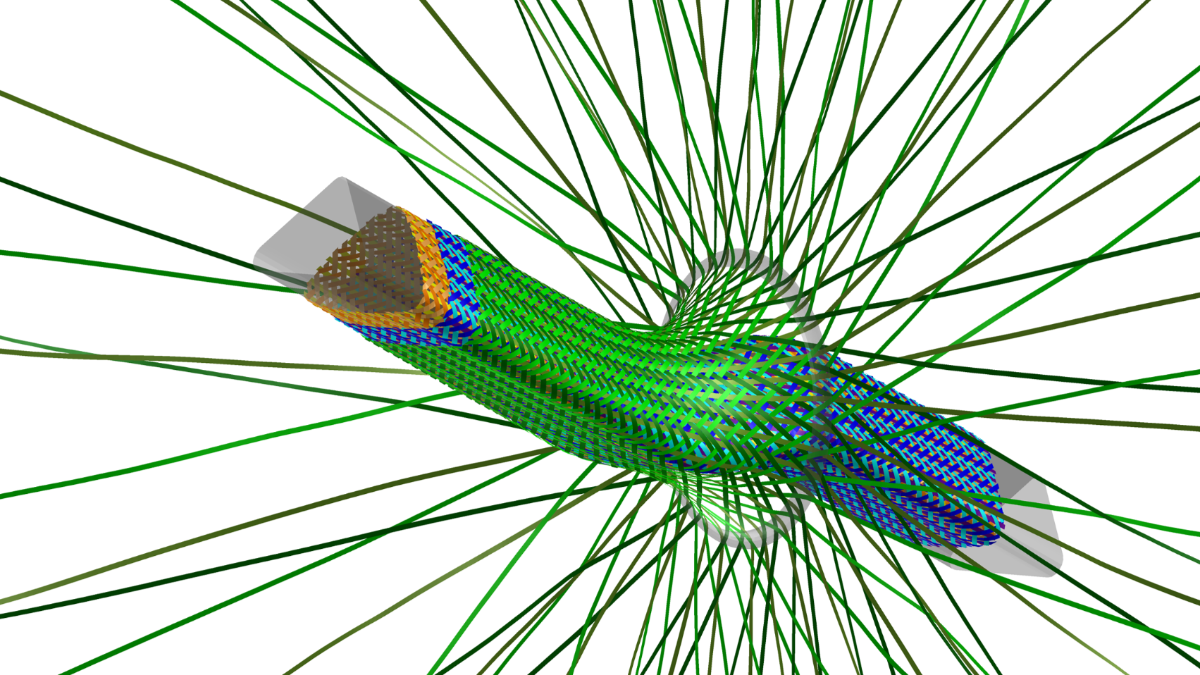

- Virtual prediction of the braid architecture

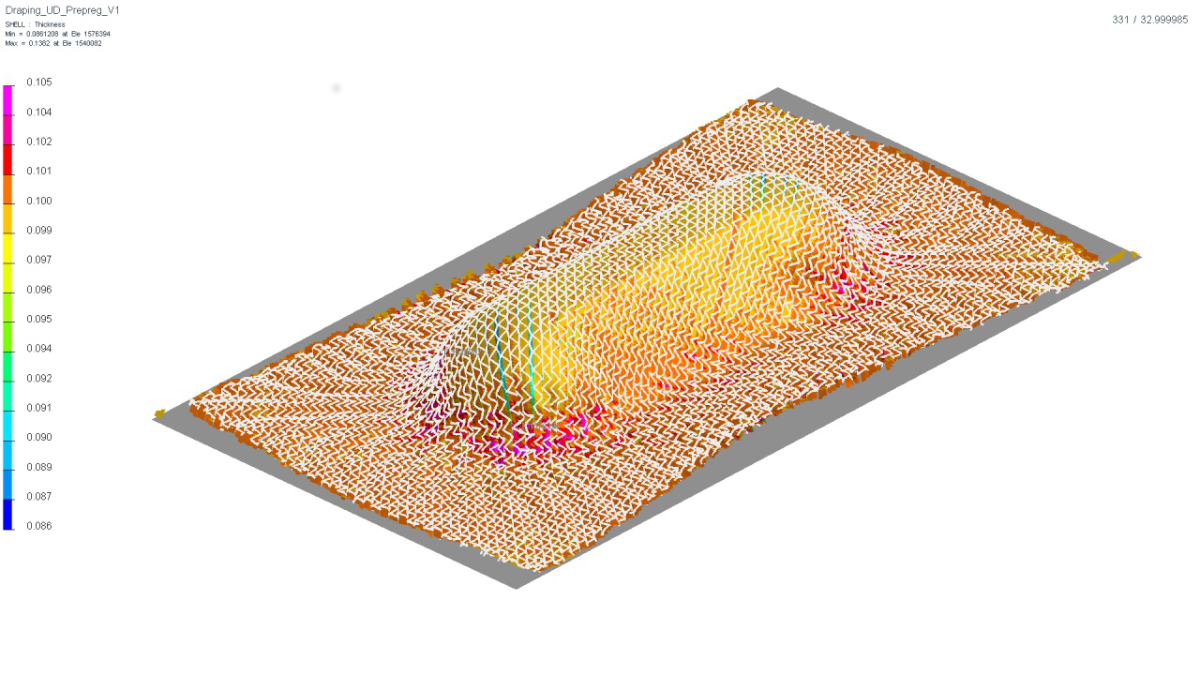

Simulation of fiber bundle deposition on a braid core and the derived generation of a near-net-shape technical braid - Draping and forming simulation of textile semi-finished products

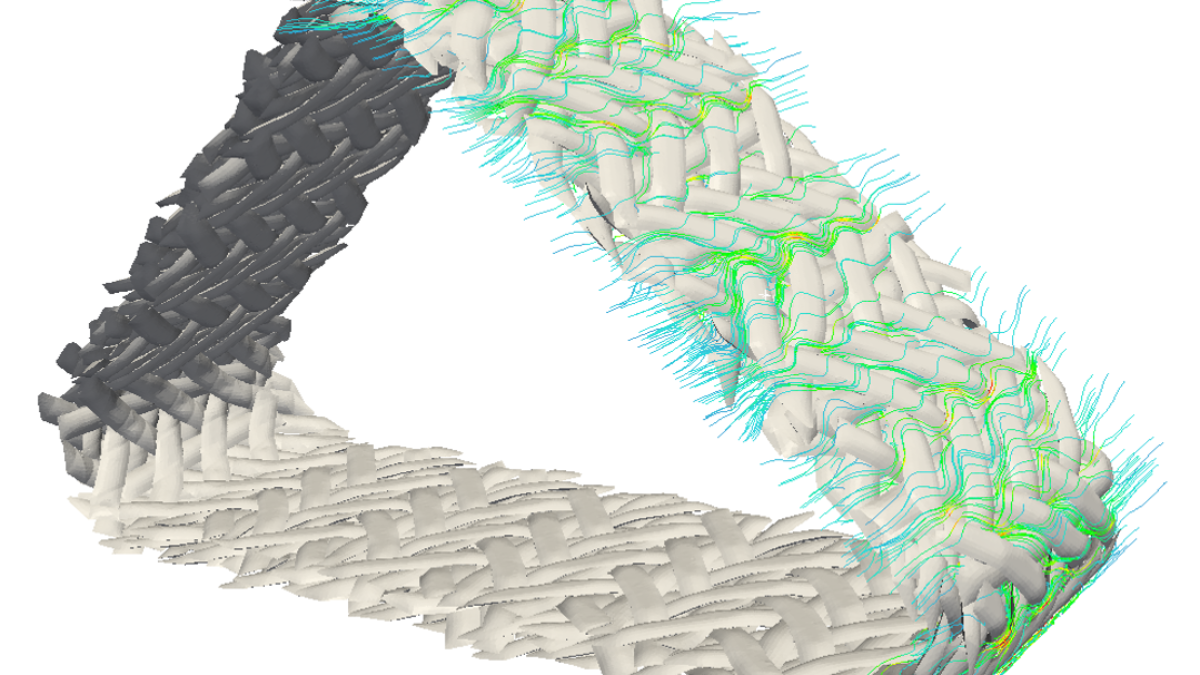

Forming simulation of the textile semi-finished product taking into account the local material behavior and the real process boundary conditions - Consideration of microscopic and macroscopic effects during infiltration simulation

Simulation of the flow front within the technical textile for the prediction of dry spots and fast runners during infiltration process

Team

Team leader

Ruben Czichos

M.Sc.Research Associate, Group leader of the Composite Simulation research group