Modern equipment operated at IFB offers a wide variety of material testing possibilities with a focus on composite materials. Quasistatic and dynamic (including fatigue) tests can be conducted for a number of specimen types ranging from coupons to large full-scale components.

Standardized tests (DIN EN ISO, ASTM, etc.) can be carried out at different temperatures. Test equipment includes two universal testing machines with different load cells (up to 250 kN), a dynamic tension-torsion testing machine (up to 100 kN) and a test field with 6 servo-hydraulic actuators (5 axial up to 250 kN, 1 torsional up to 4 kNm).

A variety of options for strain measurement is available as well. Apart from standard strain gauges we possess different types of Extensometers (mechanical and video). Complex strain field measurement is conducted with a DIC measurement system Aramis from GOM. Specimens can be conditioned e.g. for hot/wet testing at different temperatures and relative humidities in a climate cabinet.

In addition to available testing equipment, the IFB machine-shop can quickly realise individually adapted test assemblies and custom test fixtures. Test laminates and composite components can be manufactured in-house using available vacuum assisted infusion (VARI, VAP etc.), press and autoclave processing.

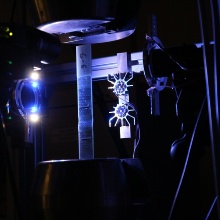

Our laboratory for thermal analysis enables the realisation of different thermal and chemical testing methods (e.g. Fiber-Volume-Ratio, DMA, DSC, TGA, etc.). Next to thermochemistry testing equipment, we are also equipped with a stereo-microscope, reflected light microscope, digital microscope and a scanning electron microscope (SEM).

For several years IFB has been in charge of testing of outgoing goods for a leading aerospace supplier. The testing process and quality assurance is audited annually.

Our testing experts are available for consultation in order to fulfil your testing requirements.

Team

Team lead

Michael May

Dr.Deputy Head of Department Lightweight Design and Simulation